Gel Coat Equipment: The Binks Gelmaster Unit

Binks Gel Coat Equipment Gelmaster

Contents

Model: 105-1138

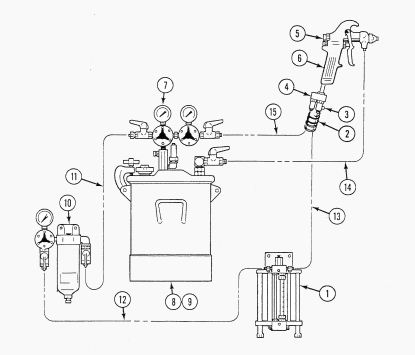

Gel-Coat System Component List

| Item No. | Part No. | Description | QTY |

| 1 | 207.11029 | Catalyst Tank | 1 |

| 2 | 102-2230 | Plug Groove Valve | 1 |

| 3 | 102-3430 | A.C.I. Valve | 1 |

| 4 | 102-265 | Side Port Control | 1 |

| 5 | 7N | Spray Gun w/ 68SS x A68PB | 1 |

| 6 | SR300-02 | Air Control | 1 |

| 7 | QMGT-5512 | Pressure Tank 20 litre | 1 |

| 8 | SFR300-02 | Regulator | 1 |

| 9 | H-2398 | Air Hose Assembly | 1 |

| 10 | H-2398 | Air Hose Assembly | 1 |

| 11 | 71-2794 | Catalyst Hose Assembly | 1 |

| 12 | H-1973-1 | Material Hose Assembly | 1 |

| 13 | H-239 | Air Hose Assembly | 1 |

What Fluid Tip Size for Spraying Gelcoat

A typical size of fluid tip for spraying gelcoat is 2.8 mm [0.110 inch]

Gel Coat Air Nozzle/Cap

Atomization Technique: conventional air spray (pressure feed)

Air consumption: see chart

Air Cap Selection Guide: see chart

| Air Cap No. | Order No. | Air Flow (lpm) | Pattern Size (mm) |

| A68PB | A68PB | 269 (@2.1bar), 400(@3.5bar), 540(@4.8 bar) | 305 |

Features

In the Binks Gelmaster unit model 105-1138 the catalyst is mixed externally, i.e. catalyst is delivered by and trough the atomisation air and is then intimately mixed with the resin leading to a clear and air free sprayed gel coat film. The advantages are that no flushing is necessary and that the external catalyst delivery is clearly visible to the operator. This model is very suitable for multi-colored operation as a quick colour change is possible.

Applications

Gel Coat on FRP (Fiber Reinforced Plastic)